Lifting Equipment Repairs

Precision repairs,

performance restored.

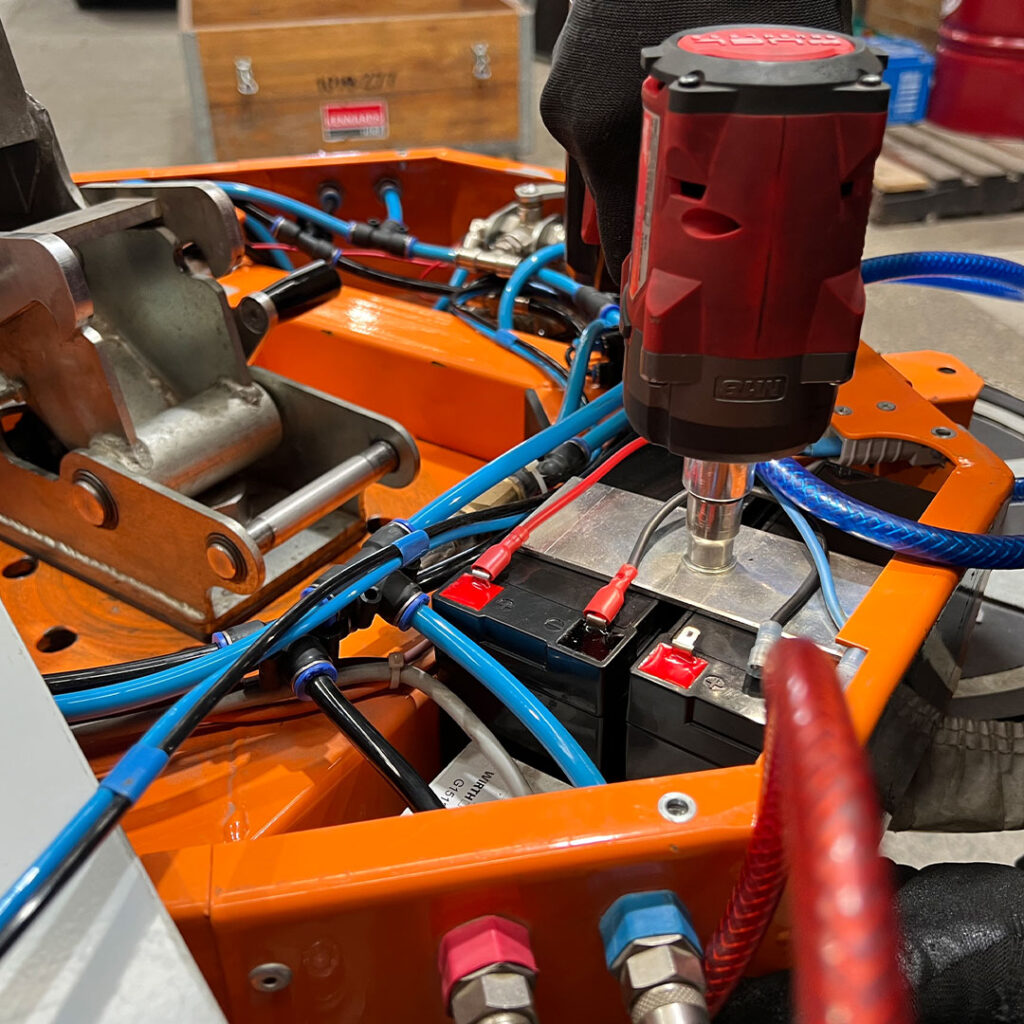

Prompt and precise lifting equipment repairs are essential to maintain both performance and safety standards. At Lincer, we specialise in comprehensive repair services focused on restoring damaged lifting equipment to optimal condition. From minor wear and tear to significant mechanical, electrical, or hydraulic issues, our certified technicians are dedicated to delivering tailored solutions that exceed industry standards.

Explore Our Lifting Equipment Repairs:

See Our Work in Action

Enquiry form for Lifting Equipment Repairs

Kindly fill out the form below to request our Lifting Equipment Repairs service, and our team will contact you shortly.

Australian Standards and Manufacturer Recommendations

At Lincer, our approach adheres strictly to Australian Standards and Manufacturer Recommendations, ensuring the highest quality and safety in every repair. Beyond surface-level inspections, we conduct a precise analysis of the damage, delving deep into the root causes and potential implications for your equipment’s functionality. By identifying underlying issues and anticipating future challenges, our repair solutions are not merely quick fixes but comprehensive remedies designed to ensure long-term reliability and performance. This commitment guarantees that your lifting equipment not only meets but exceeds industry standards, providing you with the confidence and assurance you need for your construction endeavours.

Thorough Lifting Equipment Damage Assessment

Our repair process begins with a meticulous assessment of the damage sustained by your lifting equipment. Our certified technicians carefully inspect each component, identifying any areas of concern that may compromise performance or safety. This comprehensive assessment enables us to develop a targeted repair strategy tailored to the specific needs of your equipment.

Equipment

Conditions

Documents

Markings

Equipment

configuration

Equipment

Functionality

Testing

Expert Lifting Equipment Repairs for Various Equipment

Our skilled technicians utilise industry-best practices and premium-quality replacement parts to execute repairs that prioritise durability and efficiency. Whether your equipment has suffered mechanical, electrical, or structural damage, you can trust Lincer to deliver reliable solutions that restore optimal functionality.

| Equipment |

|---|

| Glass Vacuum Lifter |

| Glass Vacuum Robot |

| Glass Vacuum Manipulator |

| Walkie Reach Stacker |

| Wire Rope Hoist Electric |

| Forklift |

| Scissor Lift |

Why Choose Lincer for Lifting Equipment Repairs

1.

Certified Experts:

Our team comprises certified technicians with extensive experience in repairing damaged lifting equipment.

2.

Tailored Solutions:

Our customer-centric approach means we’re here to support you at every step, providing transparent and efficient services.

3.

Quality Assurance:

Lincer upholds the highest standards in repair services, ensuring the safety and longevity of your equipment.

Expert repairs,

optimal performance guaranteed.

Trust Lincer for expert assessment, precise analysis, and reliable repairs of your damaged lifting equipment. Our commitment is to deliver repair solutions that guarantee optimal performance and safety, safeguarding your investment and enhancing productivity. Contact us today to schedule your repair service and experience the expertise that sets Lincer apart in the industry.

Get a visual guide from Lincer with essential insights on maintaining your Glass Vacuum Robot.

Don’t let equipment maintenance challenges hold you back. Empower your team with the knowledge they need to keep operations running smoothly.

Our Services

Lincer ensures your lifting equipment’s peak performance with thorough inspections, maintenance, repairs, and readily available parts. Discover our comprehensive suite of services below.

Inspection and Testing

Our comprehensive Inspection and Testing services vacuum lifting equipment, and material handling equipment are designed to safeguard your operations and workforce.

Schedule Maintenance

Our commitment is backed by a meticulous schedule, featuring periodic inspections, designed to proactively address any potential issues and keep your lifting equipment in peak condition.

Replacement Equipment

We offer replacement lifting equipment while yours is being serviced, ensuring your operations continue uninterrupted, keeping your projects on track.

Repairs

At Lincer, we specialise in top-tier repair services for lifting equipment. Our certified technicians are adept at addressing any damage, ensuring your equipment operates at its best.

Client Support

Access our client support page for tools to resolve issues and find technical information on lifting equipment effortlessly.

Frequently Asked Questions

Can scheduled maintenance be tailored to specific lifting equipment needs?

Yes, maintenance schedules are customised based on the type of equipment. It’s important to thoroughly check all items as per the manufacturer’s specifications and Australian standards.

How can I ensure compliance with maintenance schedules for lifting equipment?

At Lincer, we utilise maintenance management software to track schedules, set reminders for upcoming inspections, assign clear responsibilities, and maintain up-to-date documentation. Upon your request, we can notify you when the next service for your equipment is due.

Is there a difference between scheduled maintenance and repairs for lifting equipment?

Yes, scheduled maintenance is proactive and planned, aiming to prevent issues before they occur. On the other hand, repairs or unplanned maintenance address unexpected breakdowns or failures that require immediate attention to restore functionality.