In the dynamic and high-risk environment of construction, the safety and efficiency of lifting equipment are paramount. Ensuring that your lifting equipment meets all necessary safety standards and regulations is essential. This article explores the critical importance of inspecting and testing lifting equipment and provides insights into making informed decisions about inspection and testing services.

Why Inspection and Testing of Lifting Equipment is Crucial

Preventing Accidents and Ensuring Safety

Regular inspection and testing of lifting equipment are essential to prevent accidents that can cause serious injuries or fatalities. By identifying and addressing potential issues before they become hazards, you can ensure the safety of your workforce and the proper functioning of your equipment.

Compliance with Regulations

Adhering to regulations and safety guidelines is not only a legal requirement but also a moral obligation. Non-compliance can result in severe penalties, project delays, and damage to your company’s reputation. Ensuring that your lifting equipment complies with all relevant Australian Standards and safety regulations gives you peace of mind and protects your investment.

Australian Standards for Lifting Equipment Inspection

Regulations and Safety Guidelines

Using lifting equipment in construction in Australia involves strict adherence to several regulations and safety guidelines. These are designed to ensure the well-being of workers and the safe operation of equipment:

Occupational Health and Safety Act: The Occupational Health and Safety Act outlines the general duties of employers and employees to ensure health and safety in the workplace. It covers various safety aspects, including the use of lifting equipment.

Australian Standards: The use of lifting equipment must comply with relevant Australian Standards. These standards provide detailed specifications for the design, construction, and safe operation of lifting equipment.

Safe Work Method Statements (SWMS): Construction companies are required to develop Safe Work Method Statements for high-risk construction activities, including the use of lifting equipment. SWMS outline the hazards, risks, and control measures associated with specific tasks, ensuring safe performance.

Regular Inspections and Maintenance: Lifting equipment must undergo regular inspections and maintenance to ensure safe and reliable operation. Construction companies should have a systematic inspection and maintenance program to identify and address any issues promptly.

Key Aspects to Consider in the Inspection and Testing Process

- Visual Inspection and Functional Testing: Thorough visual inspections are essential to check the condition of your equipment. Functional testing assesses the performance and reliability of the machinery, ensuring it operates as intended.

- Documentation and Compliance: Ensuring that all your documents are up-to-date and ready for submission to regulatory bodies is crucial. Verifying that your lifting equipment meets all necessary documentation requirements facilitates smooth and hassle-free operations.

- Safety Marking Verification: Checking all safety markings on the equipment is a critical part of the inspection process. Proper labelling and safety signs are crucial for preventing accidents and ensuring compliance with safety standards.

- Structural Analysis: Structural integrity should be a priority. Detailed structural analysis ensures that your lifting equipment is robust and capable of handling the loads and stresses it will encounter during operation.

- Comprehensive Performance Checklists: Utilising comprehensive checklists to evaluate the performance of your lifting equipment is vital. Detailed assessments cover every aspect of the machinery, identifying potential issues before they escalate.

- Compliance Testing: Rigorous testing to ensure that your equipment complies with both manufacturer specifications and Australian standards is essential. This final step guarantees that your lifting equipment is safe, reliable, and ready for use.

Conclusion

Investing in regular inspection and testing for your lifting equipment is crucial for ensuring safety, compliance, and efficiency on your construction sites. Understanding the importance of these processes and adhering to relevant regulations and guidelines can safeguard your operations and protect your workforce. Make informed decisions about inspection and testing services to keep your lifting equipment in optimal condition and fully compliant with all relevant regulations. By prioritising safety and compliance, you can ensure the success and integrity of your construction projects in Australia.

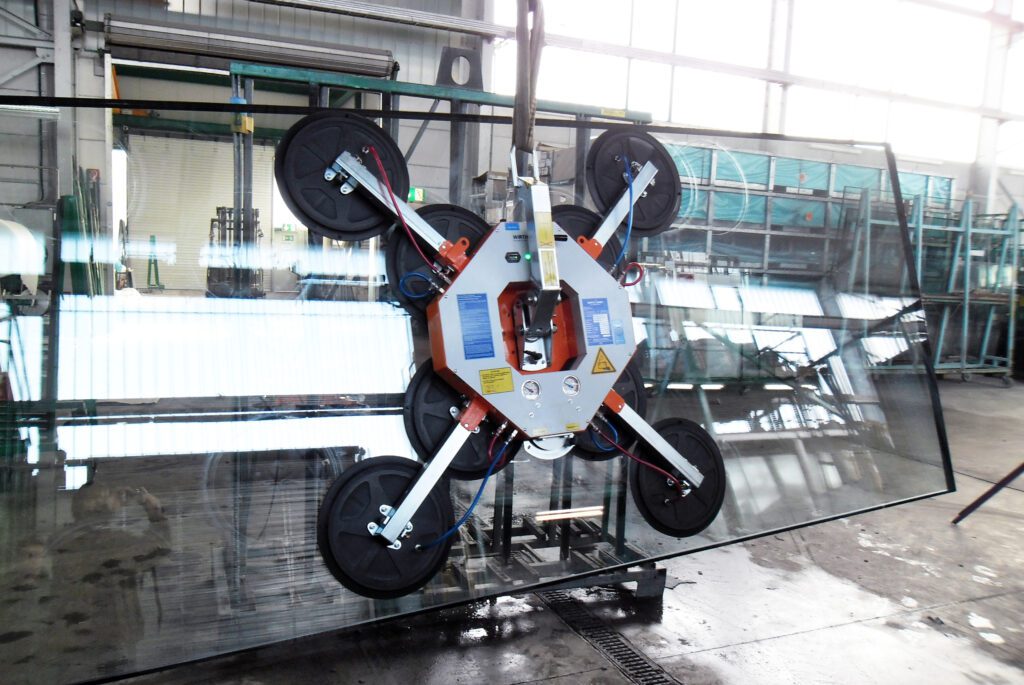

At Lincer, we understand that safety and efficiency are paramount in the construction industry. Our comprehensive Inspection and Testing services for vacuum lifting equipment, and material handling equipment are designed to safeguard your operations and workforce. Click the button below to contact us for our Inspection and Testing Services for your lifting equipment